Customer input

Improvements are ongoing and many are made based on customer input. Who can better recognize opportunities than those who use the system on a daily basis?

Refined for Asphalt

The system improves batch plants and the overall business.

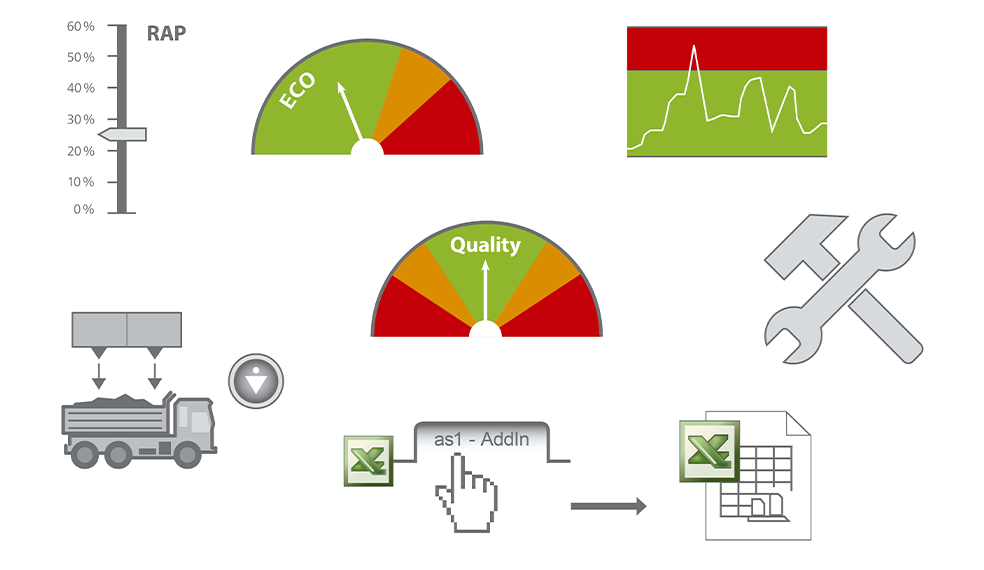

It provides statistical data that can help you uncover trends and identify areas of strength, areas where improvement is needed, and everything in between. Built-in statistical reports present in an easy-to-understand format. Data can be accessed through the Internet.

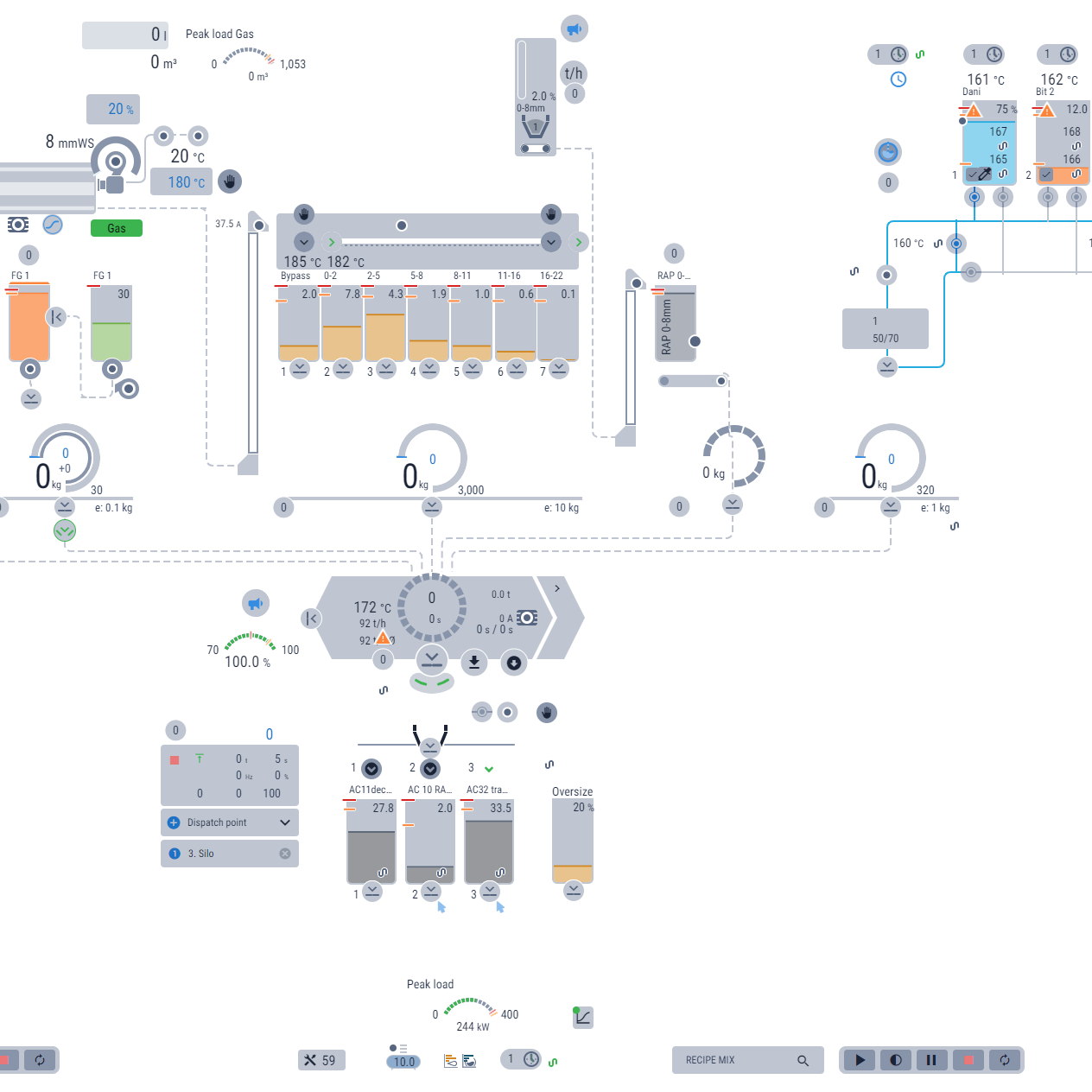

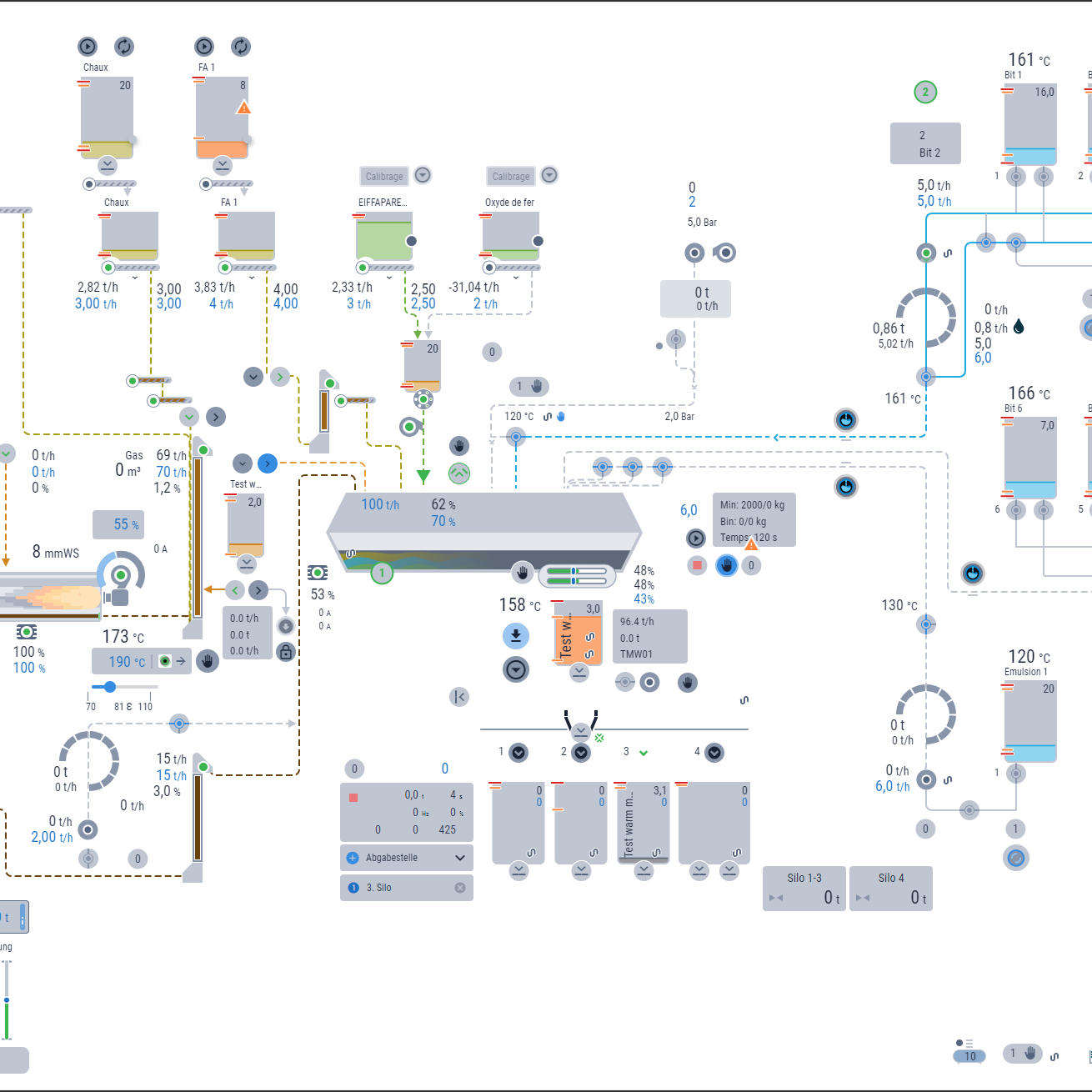

Plant operation benefits greatly, too. The system provides fully automated mix production, plus the flexibility to work in safe manual mode. It offers a host of other benefits including the use of unlimited recipes, automatic burner control, dynamic in-flight correction and full integration of electrically heated bitumen storage tanks.

Highlights

Extensive statistics available including daily reports and trending tools

Locking of silo loading based on bin content to prevent mixing of materials

Composite or individual adjustment of the feeder proportions during production

Fully automatic burner step-up and step-down system

Automatic burner control for consistent mineral temperatures

Burner diagnosis through trend graphics and display of current automatic firing system status

Production list for successive processing

Support of various dosing systems

Automatic optimisation function for aggregate-to-bitumen ratio

Automatic correction of inflight parameters

Dynamic switch point from coarse to fine batching

Wizard for feeder calibration

Convenient recipe selection via onscreen menu

“On-the-fly” recipe change

Automatic batch reduction during warm-up phase

Automatic loading bin control

Remote maintenance access and online diagnosis

Automatic connection to the Ammann service platform and exceptional support through the hotline team

The proprietary system helps plants run efficiently and uncovers valuable business data, too.

The as1 provides data that helps identify areas of strength, areas where improvement is needed, and everything in between.

Plant operation benefits greatly, too. The system provides fully automated mix production, plus the flexibility to work in safe manual mode. It offers a host of other benefits including the use of unlimited recipes, automatic burner control, dynamic in-flight correction and full integration of electrically heated bitumen storage tanks.

Highlights

Fully automatic burner step-up and step-down system

Automatic burner control for consistent mineral temperatures

Burner diagnosis through trend graphics and display of current automatic firing system status

Multiple production pre-selection for gapless/seamless production

Convenient recipe selection via onscreen menu

“On-the-fly” recipe change

Automatic loading bin control

Silo loading lock to keep material segregated

Configurable startup and step-down ramps

Graphic recipe timing view

Remote maintenance access and online diagnosis

Automatic connection to the Ammann service platform and exceptional support through the hotline team

Optional Ammann as1 modules help your plant deliver even more value.

Additional modules

Experience Our Approved Dealers and After-Sales Excellence

Contact Form

Schedule online meeting