-

Photos

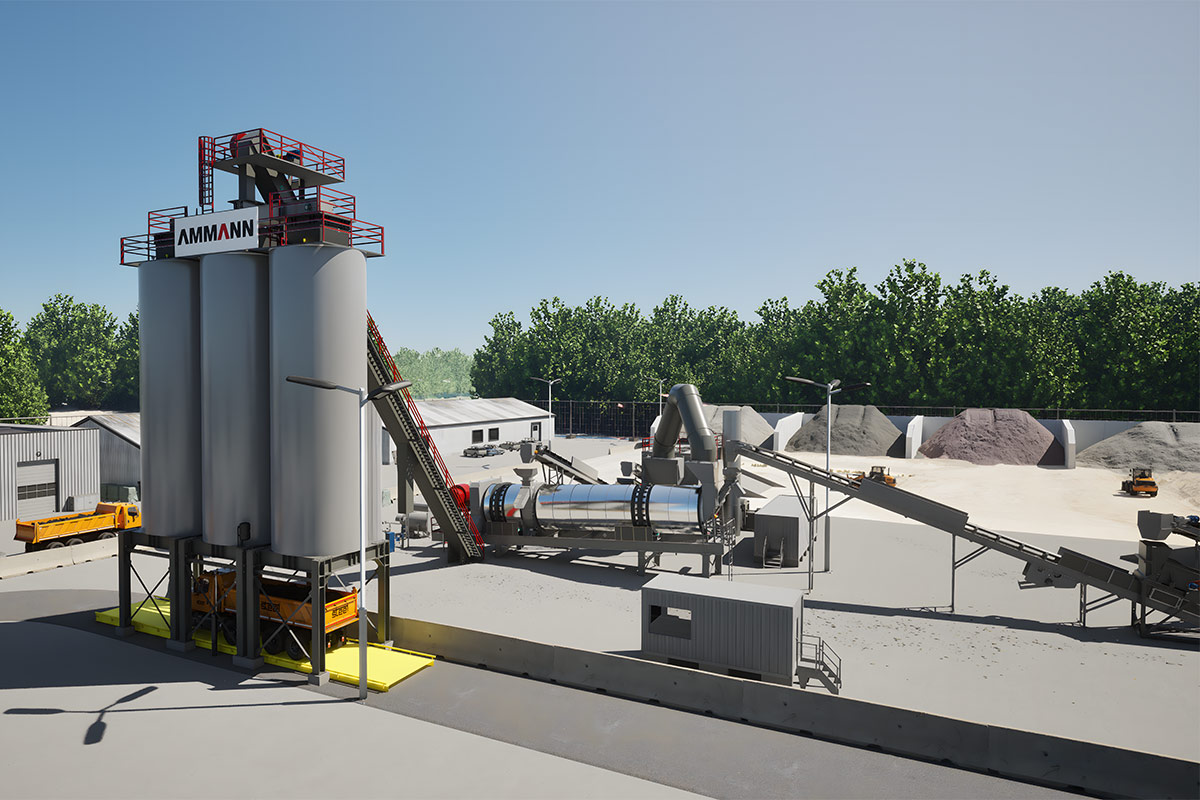

OPTIMAL RAP UTILIZATION & QUALITY MIX CONTROL

The Alpine enables HMA producers to maximize high total production of recycled asphalt pavement (RAP) content without sacrificing mix quality, utilizing Ammann’s industry-leading controls and technologies. The Alpine control system is extremely intuitive and allows tracking and analyzing plant operating data in real time to provide opportunities to gain further efficiencies over competitive equipment.

Our plants produce high-quality mix designs, including high recycled product (RAP) mix designs with typical rates of 50% standard and 60% via dual collar feed. The extended mix section of the drum allows for better heat transfer to the material and longer mixing time. The 60% RAP capabilities give the Alpine market-leading RAP content at the highest consistent quality.

The Alpine plant’s core components are also capable of seamless integration into your existing asphalt facilities for retrofit and upgrade needs.

-

Highlights

Elevated RAP Integration

Tailored for superior recycled material usage, the plant significantly increases RAP integration without impacting the asphalt mix’s quality.

Advanced Single Drum Mixing

The plant’s single drum design, complemented by an extended mixing section, ensures superior heat transfer and thorough material blending.

Smart Plant Operation

Cutting-edge control systems deliver a superior level of plant operation, allowing for real-time performance tracking and adjustments.

Modular Customization

With a modular design approach, the plant offers bespoke solutions tailored to unique production needs and project specifications.

Future-Ready Upgrades

The plant’s architecture is designed to accommodate ongoing technological advancements, ensuring your operations remain at the industry’s forefront.