Recycling

Sustainable practices for a greener future

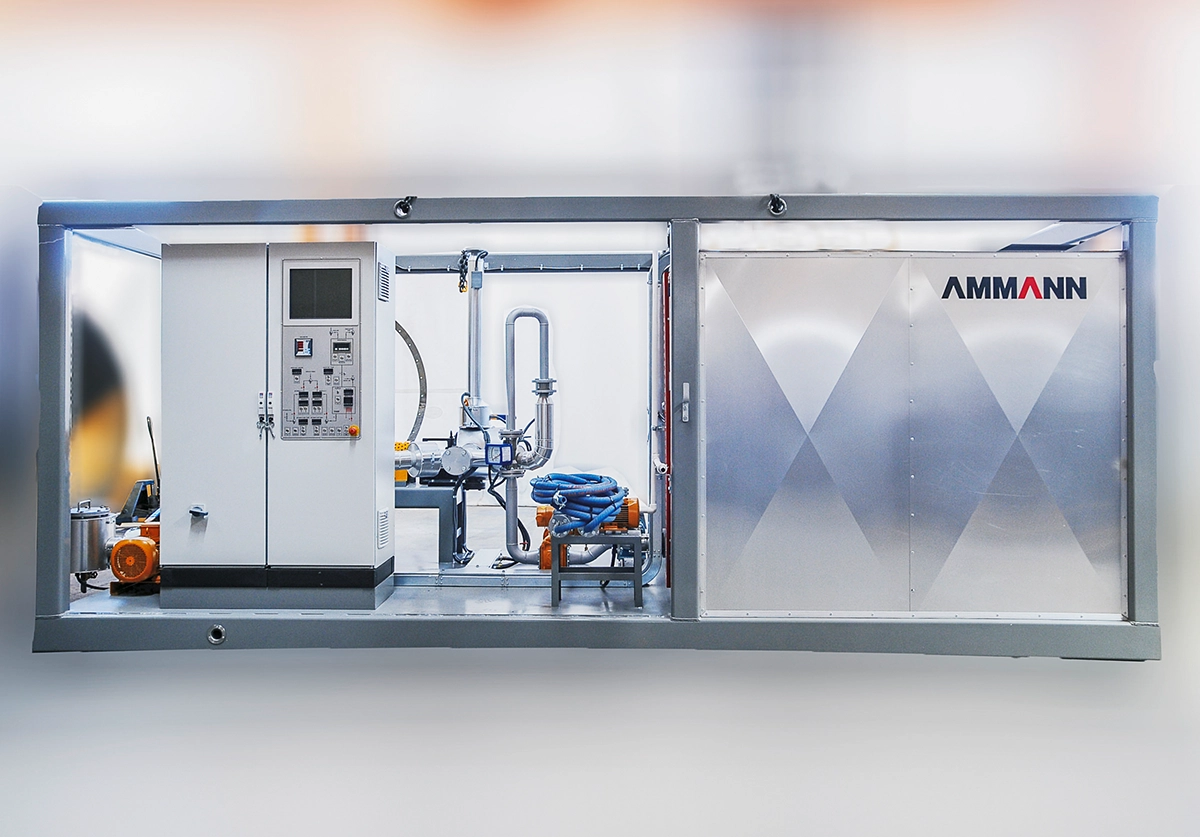

High-Production of Bitumen Emulsion

The plant features a state-of-the-art control and reporting system, ensuring precise operations and real-time data analysis for efficient emulsion production.

Semi-auto or automatic operation possibilities |

Colloidal mill |

Stainless steel premix tanks on load cells |

Heating lines for rapid heating of water |

Stainless steel pump and flow meter |

Bitumen flow meter with heated body |

Barrel pump for additional safety |

Touch screen monitor |

Experience Our Approved Dealers and After-Sales Excellence

Contact Form

Schedule online meeting