Giving customers what they really need

We asked customers, ‘What is the information you really need? What data would have an impact on your business?’

Three key themes emerged. Customers want:

Machine location

Battery status

Hours of usage

Delivering the data that matters

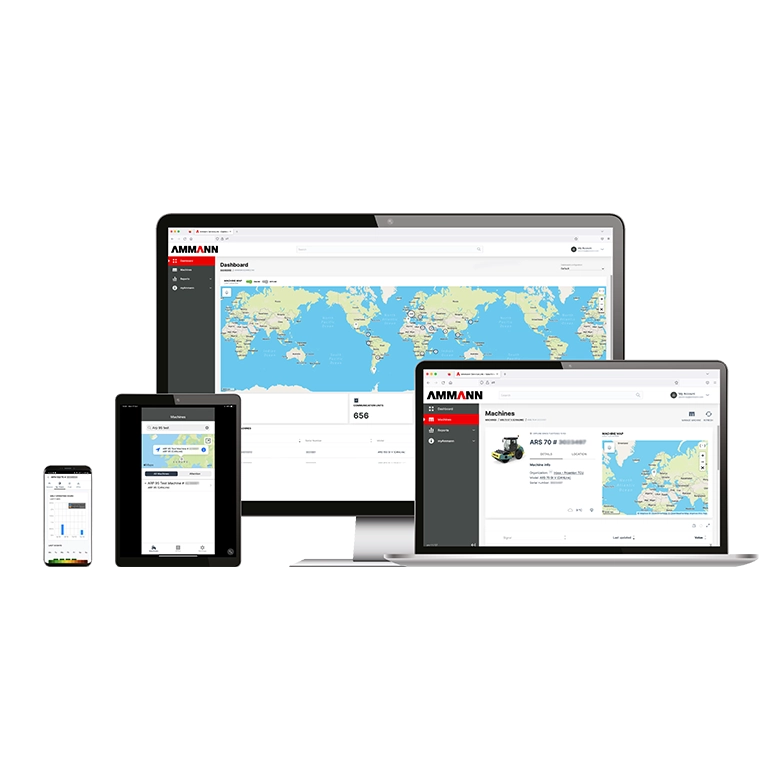

Desktop Application ServiceLink

Organize and manage multiple construction sites in the workplace.

myammann.com

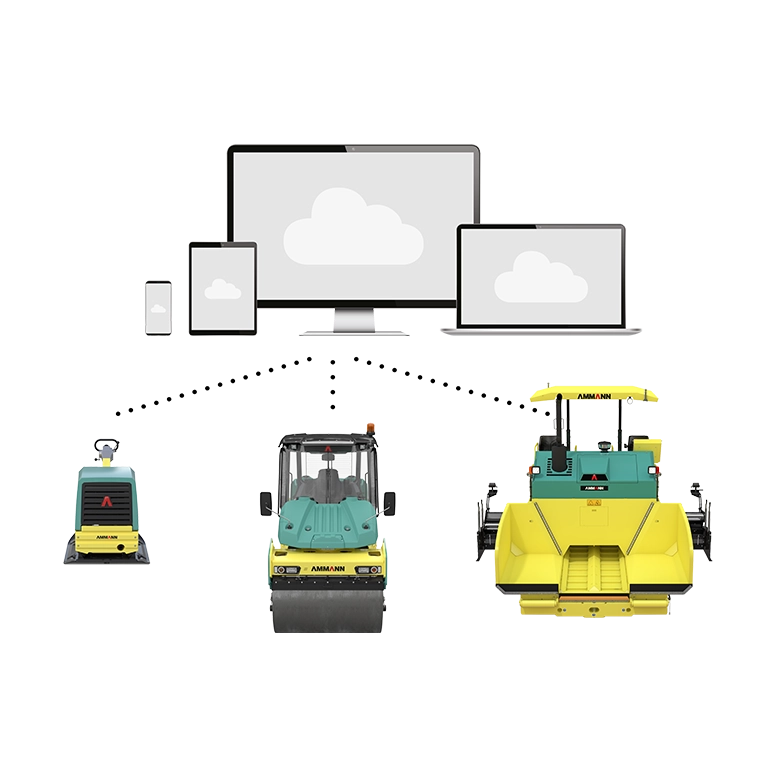

Supplies machine location, operating hours, battery status

Requires no subscription fees for Light Equipment

Provides one-click access to data

Reliably transmits data from machines, no matter where they are

Streamlines fleet upgrades (retrofit option)

Easy to install

We asked customers, ‘What is the information you really need? What data would have an impact on your business?’

Three key themes emerged. Customers want:

Machine location

Battery status

Hours of usage

Knowing a machine’s location removes guesswork for the customer, particularly if multiple jobsites are being managed simultaneously.

The location data also makes logistics (pickups and deliveries) more efficient. This, too, can have a major impact on larger fleets and rental houses.

Customers also said battery charge information is crucial. Without that data, an operator can be sent to a remote jobsite – only to discover a dead battery. A great deal of time and ultimately money is wasted on such a trip.

Hours of usage are important for rental houses and their billing. The data also helps contractors double-check jobsite usage numbers.

Experience Our Approved Dealers and After-Sales Excellence

Contact Form

Schedule online meeting