ARS 110

SINGLE DRUM ROLLERS

Tier 4f

83.9 in

23545 lb

A POWERFUL PACKAGE

BIOFUEL USE – Ammann diesel-burning machines are able to utilise hydrotreated vegetable oil (HVO), a biofuel made from waste that reduces CO₂ emissions by up to 90%.

A POWERFUL PACKAGE

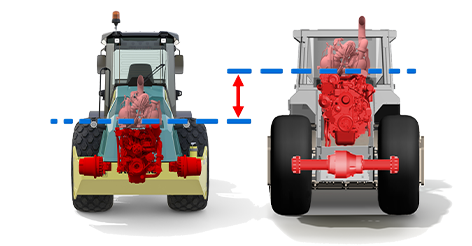

No rear axle

The compact design provides a low centre of gravity that delivers versatility by enabling traction, stability, manoeuvrability – and, ultimately, jobsite safety.

Specifications

Standard

Open platform with ROPS

Smooth drum

Steel scrapers

Diamond tread tyres

ECOdrop

Inter wheel flow divider

2 amplitudes / Multiple frequencies

Operator´s station with one drive lever (RH)

Options

A/C

A/C without cooling medium

Additional documentation printed

AmmannCare Diamond

AmmannCare Platinum

AmmannCare Gold

AmmannCare Silver

Ammann Documentation Syst. ADS

ENGINE

| ARS 110 | ARS 110 HX | - | |

|---|---|---|---|

| Emission stage | Tier 4f | Tier 4f | - |

| Manufacturer | Perkins | Perkins | - |

| Engine Model | 904J | 904J | - |

| Rating standard | ISO 14396 | ISO 14396 | - |

| Power output ISO | 134 HP | 134 HP | - |

| Exhaust Gas Recirculation | Yes | Yes | - |

| Diesel Oxidation Catalyst | Yes | Yes | - |

| Diesel Particulate Filter | Yes | Yes | - |

| Selective Catalytic Reduction | Yes | Yes | - |

WEIGHT & OPERATING CHARACTERISTICS

COMPACTION FORCES

MISCELLANEOUS

After Sales & Services

No matter where you are, Ammann-trained technicians and parts are nearby. Ammann dealers provide well-trained service technicians who can help you, whether it’s an emergency or preventive maintenance. The vast Ammann network ensures there is a nearby technician who understands your language and your technical needs. Parts availability and ease of ordering are always Ammann priorities.

Find a dealer

Experience Our Approved Dealers and After-Sales Excellence

Contact Form

Schedule online meeting

Get in touch with us to meet a sales representative near you

Contact Form

Schedule online meeting

Get in touch with us to meet a sales representative near you