Recycling

Sustainable practices for a greener future

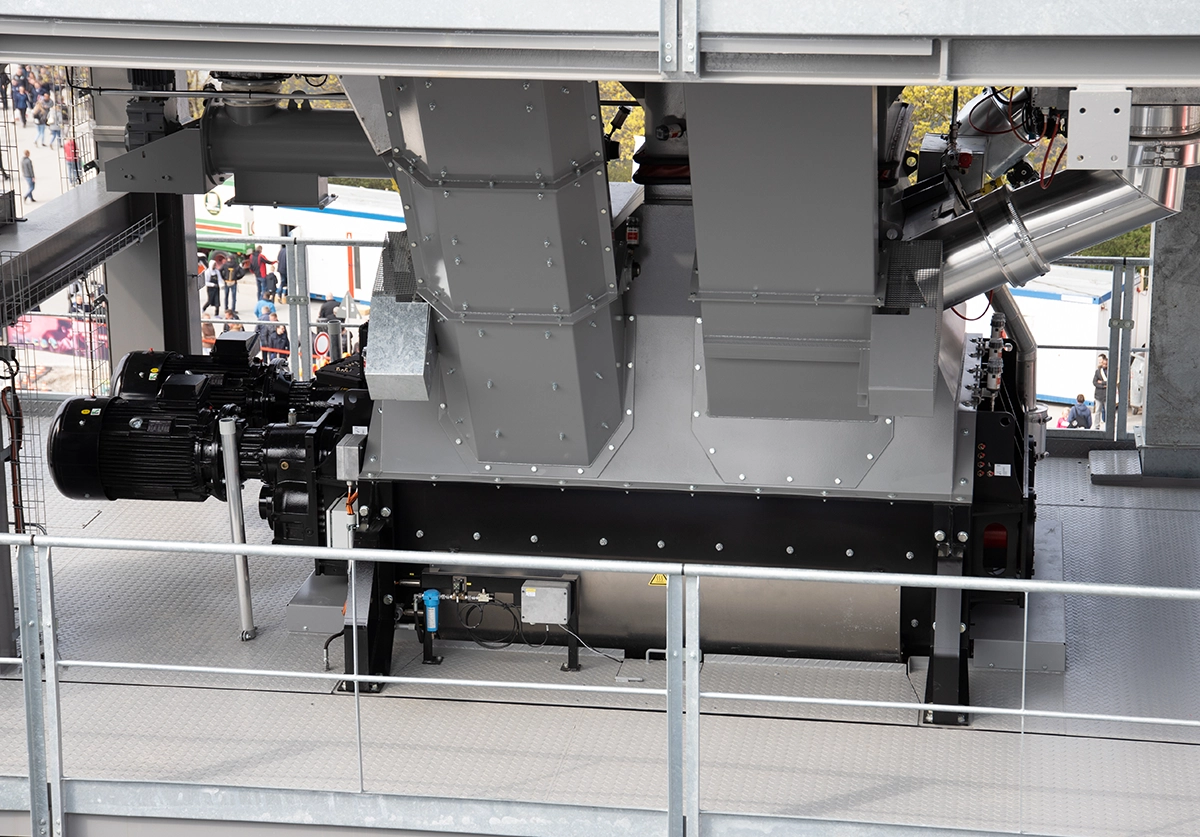

Core Components

Creating Homogenous Mix

Minimal wear through protected components and an efficient mixing proces

Compulsory twin-shaft mixer provides highest shear forces

Optimal homogeneity and mixing time through the unique Ammann paddle arrangement

Maximum sequence design flexibility that enables production of special mixes

Experience Our Approved Dealers and After-Sales Excellence

Contact Form

Schedule online meeting